Aspergillus mould

Aspergillus is a fungus that causes mould on many crops around the world. This fungus can cause problems in the Pacific, particularly when coconut is damaged by insects, or copra is not dried effectively.

Common namesAspergillus mould |

Scientific nameAspergillus flavus |

on this page: Life-cycle and identification : Symptoms : Impacts : Distribution : Prevention : Controlling Aspergillus mould : Information sources and further reading

Life-cycle and identification

Aspergillus mould is caused by a fungus that is present in air, soil and water. The fungus uses dead animal and plant material as an energy source and is often seen growing on these substrates as a saprobe (a living thing that gets nourishment from non-living or decaying organisc matter). Aspergillus spores are carried by wind, rain and insects and the fungus survives in soil and dead plant material.

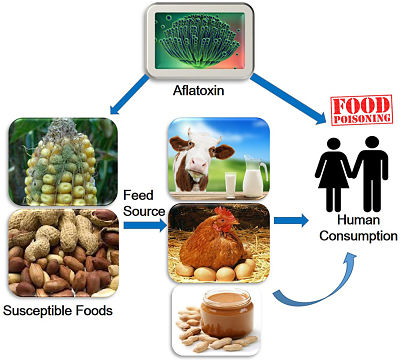

Aspergillus flavus and other Aspergillus species can produce harmful toxins called aflatoxins. The fungus and these toxins will be more prevalent in years of hot and dry weather.

The mould can survive and grow rapidly in environments with temperatures between 28-31°C, more than 85% humidity, nitrogen deficiency and drought. As these are common conditions in the Pacific, this pathogen is very hard to control.

SymptomsAspergillus mould infects copra and coconut seeds. The mould is typically a green-yellow colour and is visible on the outside of the copra or seeds. Seeds can change colour and look rotten. The fungus causes poor seed development and therefore affects seedling health. The fungus will also cause rotting of seeds and copra. ImpactsAspergillus mould can infect copra at all stages of production including the crop fields, harvesting, storage and transit. The mould can damage seeds and reduce growth of seedlings that grow from infected seed. Stored copra tends to show signs of the fungus more often than other production stages. One of the greatest impacts are the toxins the fungus can produce. These aflatoxins can cause serious harm to animals by decreasing reproduction, milk and egg production, reducing immunity and causing liver damage in pigs, poultry and other livestock. Humans can experience vomiting, high fever, water retention in limbs, jaundice (yellowing of the skin due to liver damage), and swelling and inflammation of the liver (hepatitis). The symptoms arise from an overly active inflammatory response to poisoning from inhalation or skin contact with the toxins. DistributionAspergillus mould is found all over the world, mostly on seeds and grains (see distribution spreadsheet). |

Yellow-green spores of Aspergillus flavus on copra (© Franz E. Kohler, Kohler Collection)

Aflatoxin infection path to animals and humans (© Pradeep Kumar et al.) |

in the Pacific region Fiji, Samoa, and Solomon Islands have reported copra mould.

Please check with your local biosecurity / quarantine or SPC for up-to-date distribution information.

Prevention

Poor drying and storage facilities for copra increase the chance of mould infection. During transit, further infection is possible if the copra is exposed to moisture and high heat. Insect damage can also increase the potential for Aspergillus mould occurrence. Therefore, copra should be kept dry and free from insects.

For general information on preventing pests and diseases of coconut, see the Prevention section.

Controlling Aspergillus mould

As coconut palms and copra products can be infected at all stages of production, each stage must have a control mechanism in place.

Before planting, seeds can be treated with the fungicide mancozeb (3 grams of fungicide per kilogram of seed).

During active growth the palm needs to have adequate nutrition and the best environment. Fertilisers should be applied at the recommended rates.

Only fully matured brown nuts (12 months older) should be harvested. All high quality products should be made from the mature nut which is more economical than harvesting younger nuts.

After harvest, drying copra to the right moisture content is very important. Between 24-48 hours after harvest, the copra should have a water content of 5-7%. Copra that is brittle and breaks easily is ideal.

After drying, the copra should be placed in a bag that provides good air flow and stored in a water- and insect-proof place.

The quality of the final copra product is dependent on drying the coconut kernel or reducing its moisture content from 50% to around 6%. The Food and Agriculture Organization (FAO) has provided 10 guidelines to follow for producing aflatoxin-free copra in their Coconut Post-harvest Operations Compendium (page 28). These are:

- Harvest only fully matured (brown) nuts. These are the 12-month old or older nuts;

- Do not pay the harvester for immature (green) nuts; instead penalise them for picking green nuts;

- For producers selling husked nuts to desiccated coconut factories, segregate the "fouls" for processing into copra. Never mix the "regular copra" with the copra from "foul" nuts. They tend to have high mould growth;

- When preparing copra, split the nuts and expose the meat only when certain that drying can start immediately or within four hours from splitting (exposure) to prevent mould formation. When there is the threat of bad weather, defer nut splitting;

- If the weather suddenly turns bad during the sun-drying period and is expected to remain so for some time, use of mould inhibitors is recommended;

- For producers practising sun drying, maintain cleanliness in the drying area. Clean pavement or floors before spreading fresh coconut meat. Make sure that soil and other extraneous matters are not mixed with the meat. Plastic sheeting may be used under the coconut meat to avoid direct contact with the ground;

- Have on hand a portable cover (plastic sheeting) to protect coconut meat from rain and dew. These are shaped like roofing (inverted Vs) to allow aeration. On extended downpours, heat and dry the copra within 24 hours;

- Continuous sun drying for four to five days (in good sunlight) shall achieve 6 percent moisture content;

- For producers using smoke, kiln dryers, and other types of dryers, a drying temperature of 35°C to 50°C should be maintained for the first 16 hours of drying followed by 50°C during the next phase until a final moisture content of 6 percent if reached. It is important that drying should begin four hours after the nuts are split to prevent mould contamination;

- Pressing the copra between the thumb and forefinger, the thumb against the whitemeat is a quick test for 6 percent moisture content. If the copra kernel (white portion) does not stick to the thumb, and readily drops when released, the 6 percent (approximately) moisture level has been achieved.

To reduce Aspergillus mould growth in the soil, crop rotation with rice or vegetables where possible is recommended.

Information sources and further reading

Food and Agricultural organization (FAO). 1999. Coconut Post-harvest Operations Compendium. pages 1-39

Food and Agricultural organization (FAO). 2018. Technologies and practices for small agricultural producers; Copra Processing. [ONLINE]

Kumar et al. 2017. Aflatoxins: a global concern for food safety, human health and their management. Frontiers in Microbiology, 7: 2170.

PestNet. 2017. Coconut Aspergillus mould. [ONLINE]

TNAU. 2018. Expert System for Coconut; Harvest and Post Harvest. [ONLINE]

content reviewed by Merje Toome, Plant Health and Environment Laboratory, Ministry of Primary Industries, New Zealand, October 2018